Plastic injection moulding is most likely the most in-need manufacturing techniques for manufacturing plastic components and factors at scale. Known for its precision, effectiveness, and flexibility, injection moulding is employed across several industries—from automotive and electronics to purchaser products and health-related products.

What's Plastic Injection Moulding?

Plastic injection moulding consists of injecting molten plastic inside a pre-developed metal mould under higher stress. The plastic cools and solidifies In the mould, utilizing the product of the final item. As soon as the aspect is entirely cooled, It really is ejected from the mould along with the cycle begins once more. This method is particularly repeatable, rendering it perfect for mass manufacturing.

Crucial Advantages

One particular from your big benefits of plastic injection moulding is having the ability to produce elaborate designs with wonderful accuracy and regularity. It’s also hugely Charge-helpful for high-quantity operates, Because the very same mould might be utilized to deliver 1000's—or simply hundreds of thousands—of equivalent pieces with small product squander.

Furthermore, various plastics can be used in the procedure, like engineering-grade polymers like ABS, Nylon, Polycarbonate, and Polypropylene. These products present a variety of qualities which include versatility, toughness, chemical resistance, and thermal stability, with regards on the software.

Applications Across Industries

Plastic injection moulding is utilised in virtually every single marketplace. In automotive producing, it should help make dashboards, clips, and housings. In healthcare, it’s used to make professional medical-grade syringes, containers, and system casings. Electronics makers rely on it for generating tough plastic enclosures, buttons, and connectors.

Tooling and Mould Style

The standard of a last products depends intensely with regards to the style and design in the mould. Toolmakers use CAD application to produce precision moulds, that happen to be commonly comprised of hardened steel or aluminium. Whilst the initial price of mould development may very well be higher, the here lengthy-time period creation performance causes it being a gratifying expenditure for giant-scale jobs.

Sustainability and Recycling

Present day plastic injection moulding amenities can also be adopting far more sustainable techniques. Leftover plastic content is frequently reground and reused. Providers like Australian Consolidated Plastics even deliver plastic recycling products and services for products like Acrylic and Polycarbonate, selling a circular economic climate in producing.

Summary

Plastic injection moulding stays a cornerstone of modern day manufacturing. Its performance, versatility, and capacity to supply consistent excellent be certain it's by far the most well-liked variety for corporations needing trusted, significant-volume plastic manufacturing. As products and systems evolve, the process will keep on to are more sustainable and complex—Assembly the stress of industries worldwide.

Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now! Tonya Harding Then & Now!

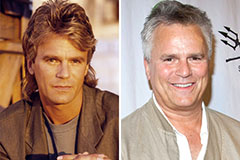

Tonya Harding Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!